Our birds are constantly on the move, thriving in an environment with grass, bugs, and fresh air.

Raised with the attention we give them, grass fed cattle contribute to environmental regeneration.

No corn, no grain byproducts, no antibiotics. It doesn’t need to be complicated!

We send out orders once each week to customers in New York, New Jersey, Pennsylvania, Delaware, Connecticut, Rhode Island, Massachusetts, Vermont, New Hampshire, Maine.

Shop Our Store

Welcome to Wrong Direction Farm

At Wrong Direction Farm, we choose to take a different path. We aren’t chasing bigger and better. We simply want to produce great food in a way that treats our land, our animals, our family, and our customers with respect.

From the Shop

Know your Farmers

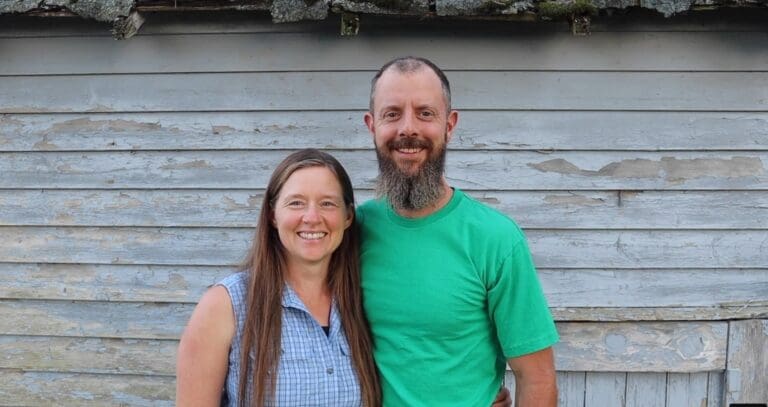

Connect with the farmers, not just a marketing department.

Meet Rachel and Dave Perozzi, your farmers at Wrong Direction Farm.

People Are Saying

“Your turkey was the best ever”

“We’ve officially been converted to WDF meats.”

“I am a very satisfied customer!”

From the Blog

The Best of Our Farm to Your Door

Each week we send orders of grass fed beef and lamb, pasture raised chicken, turkey, and pork from our farm directly to homes throughout the Northeast. Your order will be sent with dry ice for next day delivery, so everything will arrive ice cold.

Delivery

Customers in the Northeast get free delivery on orders over $200. We deliver throughout New York, including all of New York City and Long Island, and most of the Northeast.

Responsibility

Nobody likes wasteful styrofoam, so instead we use fully recyclable, paper-based insulation for our shipping containers. Box and insulation can be recycled together in any curbside pickup.